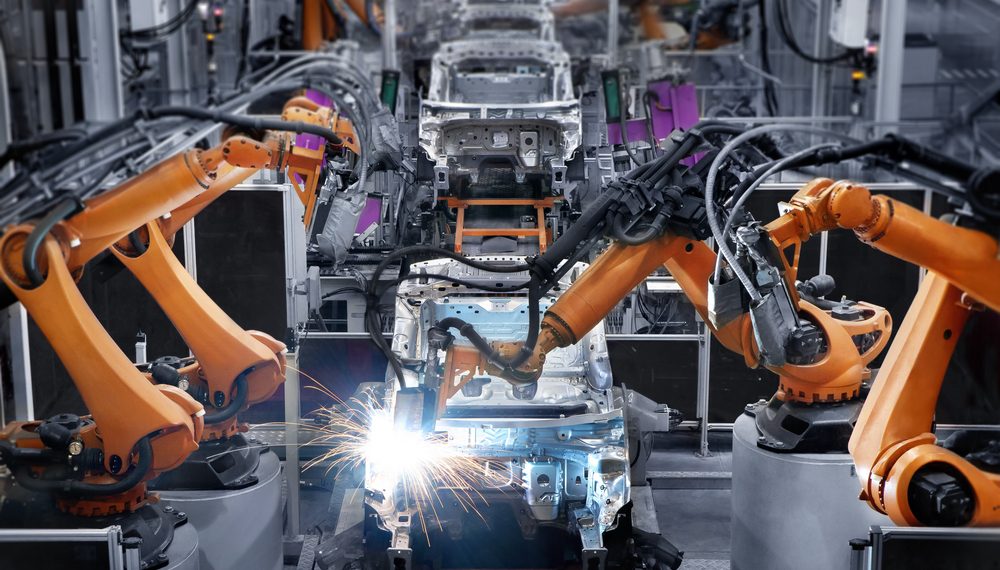

In today’s modern world, manual welding procedures are transformed into the latest cutting-edge technology. This latest innovation in the welding field has created several benefits for welders. Now, remarkable robotic welding machines have made the welding process easy. These automatic machines have made welding more convenient for handling heavy construction machines. The latest technology of automated welding machine Dubai transformed the welding landscape by providing efficient and precise welding results.

What are robotic welding machines?

Robotic welding machines are advanced technologies that use robots to perform welding tasks and gives exact and efficient results. These robots are equipped with welding tools and all necessary equipment, including torch, lasers, and electrodes. They can conveniently perform a diverse range of welding procedures. Welding machines also contain several essential features. Robotic welding machiene Dubai has made the welding process more automatic. It is used to hold heavy machinery and welding tools and move them correctly along with the welding needs. The controller is considered the brain of welding robots. It is specified with programming algorithms that can direct the movement of robots. It is also essential to adjust the welding parameters and control various other systems used for the welding procedure. Welding tool is another central part of welding robots.

The type of welding tool depends upon the application. Most welding tools such as laser torch for any other specific equipment that is necessary to control the particular welding task. Sensor is permanently integrated into the robotic systems. The primary role of sensor is to provide feedback to the robot and the other parts of the robot’s to work accordingly. Different types of welding tasks can be controlled at a distance from the welding material. It is also helpful for time adjustments according to specific procedures and welding needs.

Working of robotic welding machines

Robotic welding machines are specifically designed to perform diverse welding procedures, with minimal human interaction, and can create ease for welders.

Programming is the starting step to initiate any robotic system. A skilled operator uses specific parameters to set the robot’s programming to follow a particular procedure. The machine then gives this path a complete adjusted details of welding speed time and directions to the material that is needed is carefully positioned in the robotic setup. The welding parameters, including current, voltage, speed, are set up to start the welding procedure. These parameters are set up by considering the type of welding material and desired weld quality.

After ensuring all these setups, the welding robots start working. The programmable tools move the welding peace, and the robot sensor monitors the process carefully. They adjust and maintain the distance of welding materials to perform quality welds.

Robotic welding machines in Dubai

Dubai is now evolving into the industrial landscape. In this sense, the remarkable innovation of robotic welding machines is playing a prime role in the diverse industrial areas. These automatic machines apply to various manufacturing, construction, and automotive industry sectors. Multiple companies in Dubai are adopting the latest technology of automated systems to get speedy and quality results. These machines are helping industries of Dubai to overcome all welding challenges.