Lever handles play a major role in the mechanical industry. The handles act as a necessary device for many important tasks.

So if you do not know what a lever handle is, you should try to learn about them.holdbarhet nespresso kapsler

vinglas boda nova

qatar airways handgepäck gewicht

חוק רמקולים תחת כיפת השמיים

כורסא אגורה

nike tech fleece tapered joggers in blue

dámské jarni kotníkové boty tamaris

best apple watch bands for women

dežna obleka za otroke

spodnje hlače moške

Lever Handles: What are They?

A lever can be thought of as a straightforward mechanism made out of a beam or stiff rod that is pivoted at a fixed hinge or fulcrum. A lever can be used to provide a force to a weight. You will therefore have a mechanical advantage.

Lever handles are used in a variety of industries, from packaging to office supplies. By turning the handle, the levers enable effective tightening and loosening of screws.

A lever handle is a rigid body that can rotate around a point on itself. Based on the locations of fulcrum, load, and effort, the lever is divided into the following types:

- flat lever handles

- levers with spherical knobs

- clamping nuts with double levers

- ratchet spanners

- split hubs

As a result, you should buy a lever handle based on your needs. However, you must make sure that the lever handles you choose for your industrial applications are of high quality.

Lever handles are also available in a variety of materials. Thus, you must be careful when selecting the material. For heavy purposes, for instance, cast iron is an option. Additionally, they are available in super-technopolymer with stainless steel inserts for fast and reliable clamping.

Additionally, there are lever handles with a tightening force adjustment system and a special ring to secure it in the desired position.

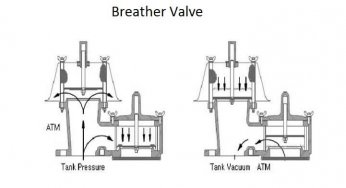

Breather Valves:What are They?

Breather valves are yet another essential tool for the mechanical engineering sector. In atmospheric and low-pressure storage tanks, they serve as a pressure release valve and a safety measure.

Due to the increased pressure, breather valves are useful in preventing explosions in tanks. Additionally, they can stop the inside of the storage tanks from collapsing as they are being filled or emptied. The vacuum may be reduced as a result of the collapsing, which could cause implosion.

The values keep the vapor inside the tank until the tank reaches the desired pressure. Furthermore, while in the out-breathing mode, breather valves can safeguard the storage tank.

Uses of Breather Valves

Breather valves are useful for regulating inhalation and exhalation to safeguard the storage tank.

A storage tank needs a suitable vent that is matched to it in order to breathe in and out correctly and control the pressure inside.

The loading and unloading processes are typically when the tank breathes in and breathes out. Breather valves can shield tanks from vacuum-induced collapse or overpressure-induced rupture.

Storage tanks and vessels must have venting mechanisms to prevent pressure buildup that could cause an explosion.

For instance, a storage tank storing flammable liquid requires the installation of breather valves to allow it to breathe and minimize evaporation loss. Otherwise, there is a chance of an explosion.

Selecting a Breather Valve: Practical Tips

Carefully consider the breather valve you choose. You must be sure that the breather valve you choose will lessen the potential for moisture to enter the container.

Keep in mind that the valves are there to protect the tank or container against high pressures and vacuums. As a result, you must make sure that the breathing valve is always sealed, barring the airlift and extremely hot weather.

Therefore, you need to check the following factors while selecting a breather valve:

- The maximum pressure and vacuum handling capability

- The volume, it can handle

- Speed of pressure change

Conclusion

Finally, if you want high-quality devices, you should pick a reputable manufacturer. Therefore, before making a purchase, take some time to choose a reputable manufacturer.